Rubber Powder Modified Asphalt The Future of Paving Across Asia, Europe, and Africa

Rubber Powder in Modified Asphalt: The Future of Paving Across Asia, Europe, and Africa

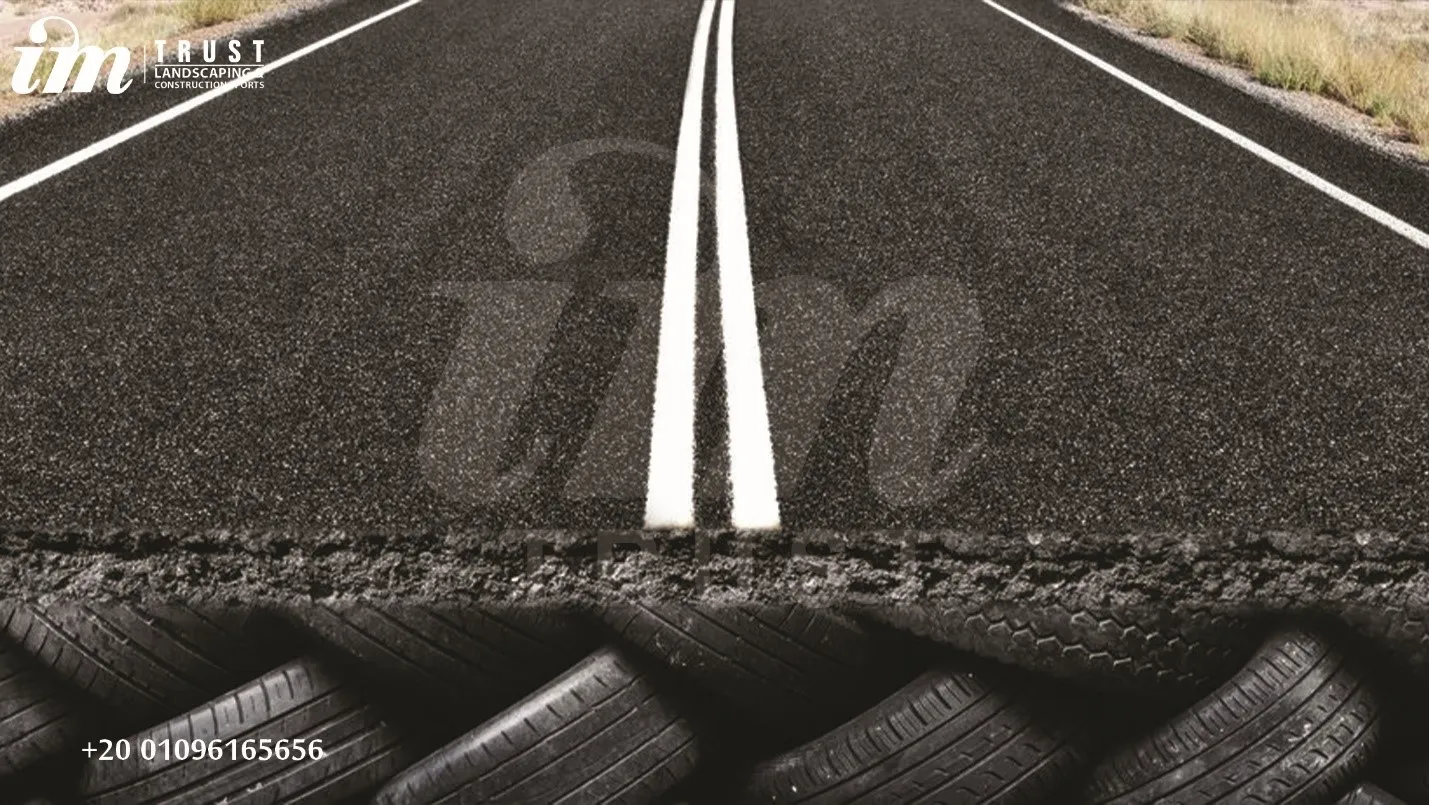

The incorporation of rubber powder into modified asphalt represents a transformative leap in road construction technology. This innovative approach not only promises enhanced durability and performance of road surfaces but also heralds a new era of eco-friendly infrastructure development. Countries across Asia, Europe, and Africa are increasingly adopting this sustainable solution, leveraging the myriad benefits it offers to meet the demands of their diverse climates and terrain. From the bustling streets of Thailand and China to the expansive highways of Saudi Arabia, all the way to the varied landscapes of Europe and the developing roads of Africa, rubberized asphalt is paving the way for a more resilient and sustainable future.

Introduction to Rubber Powder in Modified Asphalt

Utilizing rubber powder in asphalt modification is not merely a technical enhancement; it’s a strategic approach to sustainable construction. In regions like Thailand, China, and Saudi Arabia, where road durability is tested by extreme weather and heavy traffic, the resilience offered by rubber-modified asphalt is invaluable. Similarly, in Europe’s temperate climates and Africa’s varied terrains, this innovative material contributes significantly to longer-lasting roads, thereby reducing maintenance costs and environmental impact.

Technological Advancements in Rubber Powder Modification

Advancements in technology have played a crucial role in refining the process of integrating rubber powder into asphalt, making it a feasible option for widespread use. These innovations ensure that roads in countries like Thailand, China, Saudi Arabia, and beyond not only withstand the test of time but also contribute to environmental sustainability by repurposing waste materials.

Case Studies: Success Stories from Asia, Europe, and Africa

Across continents, from the heat of Saudi Arabia to the humidity of Thailand, the chill of Europe to the diverse climates of Africa, rubber powder in modified asphalt has proven its worth. Each successful implementation showcases the potential of this material to revolutionize road construction, offering insights into its adaptability and effectiveness.

Environmental Benefits of Using Rubber Powder in Asphalt

The environmental implications of adopting rubberized asphalt are profound. By recycling waste rubber into roads, countries across Asia, Europe, and Africa are not only mitigating waste but are also reducing their carbon footprint. This aligns with global efforts to combat climate change, presenting a model for sustainable development.

Challenges and Future Prospects

Despite its benefits, the adoption of rubber powder in modified asphalt faces challenges, from technological barriers to initial costs. However, the future looks promising as research and development in regions like China, Thailand, and Saudi Arabia, extend to Europe and Africa, aiming to overcome these hurdles and cement the place of rubberized asphalt in future road construction.

The Use of Rubber Powder in Modified Asphalt and the Role of IM Trust Company in its Production

our Top-Quality Rubber Granules

Elevate Your Projects with Top-Quality Rubber Granules! 🏗

Black Asphalt Crumb Rubber / Rubber Powder Modified Asphalt

Black Asphalt Crumb Rubber / Rubber Powder Modified Asphalt

Rubber powder is considered a vital and effective additive in enhancing the properties of modified asphalt. It’s an innovative

technique widely used in road construction and infrastructure. Modified asphalt is distinguished by

a certain percentage of added rubber powder, which enhances its flexibility, resistance to wear and tear, and improves its performance under various conditions.

IM Trust Company plays a leading role in the production of high-quality rubber powder and rubber granules used

to enhance the properties of modified asphalt. The company’s production lines are equipped

with the latest technologies and equipment, allowing for the production of the best types of rubber powder and granules with high quality and competitive prices.

IM Trust: Your Top Choice for High-Quality Rubber Powder Modified Asphalt!

Thanks to its capability to produce large quantities of rubber powder and granules monthly,

IM Trust Company can meet the global market demands and satisfy customers’ requirements

effectively. The company’s policy of exporting its products worldwide makes it a preferred choice

for many large companies and projects around the globe.

In summary, the use of rubber powder in modified asphalt is an innovative and effective technique to

improve the quality and enhance the resistance and flexibility of asphalt. With the quality of IM Trust

Company’s products and its ability to meet global market demands, it’s considered a reliable partner

in infrastructure and road improvement worldwide.

🔍 Are you searching for the ultimate solution in sustainable, high-performance materials?

Look no further! Our eco-friendly rubber granules, available in versatile black and vibrant colors, are your perfect choice

. Crafted from premium SBR rubber, these granules offer unparalleled durability and cost-effectiveness, making them

ideal for sports surfacing, playground safety, and numerous industrial applications.

Technological Advancements in Rubber Powder Modification

The integration of rubber powder into asphalt signifies a notable shift towards more

sustainable and resilient road construction methodologies. This shift is underpinned

by several technological advancements that have not only optimized the use of

rubber powder in modified asphalt but also set new standards for road quality and longevity.

Innovative Processing Techniques

Initially, the process of incorporating rubber powder into asphalt faced challenges related to

compatibility and performance consistency. However, through continuous research and technological innovation, methods such as the wet process, where rubber powder is mixed with bitumen before combining with the aggregate, and the dry process, where

rubber powder is mixed directly with the aggregate, have been refined.

These processes have improved the homogeneity of the asphalt mix,

ensuring that the rubber particles are evenly distributed. This uniform distribution is crucial for the enhanced flexibility and durability of the pavement.

Enhanced Performance Attributes

The technological enhancements in rubber powder modification have directly translated to superior

road performance characteristics. Rubber-modified asphalt exhibits higher resilience to temperature variations, reduced susceptibility

to cracking and rutting, and better noise reduction properties. Specifically, the elastic nature of rubber contributes

to a significant decrease in the formation of cracks and potholes, leading to a longer lifespan of the road surface.

Environmental and Economic Benefits Rubber Powder Modified Asphalt

Advancements in rubber powder technology have not only elevated the quality of road construction

but also brought forth environmental and economic benefits. The use of recycled tires in asphalt production

not only helps in managing waste but also reduces the reliance on petroleum-based bitumen, contributing

to a lower carbon footprint. Economically, the increased durability of rubber-modified asphalt roads means

reduced maintenance costs and longer intervals between resurfacing, offering substantial cost savings over the pavement’s lifecycle.

Case Examples from Targeted Regions

Countries across Asia, Europe, and Africa are beginning to recognize the value of these

technological advancements. For instance, Thailand has implemented rubber powder

in modified asphalt in various infrastructure projects, witnessing a notable improvement

in road resilience and performance. Similarly, China’s commitment to

eco-friendly road construction has seen an increase in the adoption of rubber-modified asphalt, leveraging t

he country’s extensive rubber production capabilities. In Europe, countries

like the UK and Germany are exploring the benefits of this technology in their quest for more sustainable

infrastructure solutions. Meanwhile, in Africa, nations such as South Africa are conducting trials to assess

the viability of rubber-modified asphalt in their climates and road conditions.

Future Prospects Rubber Powder Modified Asphalt

The future of rubber powder in modified asphalt looks promising, with ongoing research aimed

at further enhancing the compatibility and performance of rubber in asphalt mixtures. As the global

community continues to prioritize sustainability and durability in road construction, the demand for

innovative solutions like rubber-modified asphalt is expected to rise. This upward trend presents

a significant opportunity for countries worldwide to adopt these technological advancements, paving

the way for more resilient and eco-friendly road networks.

Global Success Stories: Rubber Powder Modified Asphalt in Action Across Continents

The adoption of rubber powder in modified asphalt is a testament to global innovation in sustainable infrastructure.

The adoption of rubber powder in modified asphalt is a testament to global innovation in sustainable infrastructure.

From the bustling streets of Asia to the diverse landscapes of Europe and the challenging terrains of Africa, rubberized asphalt has

demonstrated its versatility and effectiveness. Here, we explore how different regions are harnessing this technology to

achieve long-lasting and eco-friendly road solutions.

Asia: Leading the Way in Rubberized Road Solutions

In Asia, countries like Thailand and China have emerged as frontrunners in the application

of rubber-modified asphalt. Thailand, leveraging its status as one of the world’s largest rubber producers, has extensively

integrated rubber powder into its road construction projects. This initiative not only boosts the local economy by utilizing

domestic rubber but also enhances road quality and longevity, showcasing significant improvements in resistance

to wear and tear caused by heavy traffic and tropical weather conditions.

China, on the other hand, has focused on innovation and sustainability in

its road construction efforts. By incorporating rubber powder into asphalt, China has been able to address urban noise pollution

and improve road durability, setting a benchmark for large-scale urban infrastructure projects.

Europe: Pioneering Sustainable Road Construction Practices

Europe’s approach to rubberized asphalt focuses on environmental sustainability and

resource efficiency. Countries like the United Kingdom and Germany have initiated projects that

utilize rubber powder from recycled tires, contributing to waste reduction and environmental conservation.

These projects not only demonstrate the feasibility of rubberized asphalt in temperate climates

but also align with Europe’s stringent environmental regulations and goals for sustainable development.

Africa: Overcoming Challenges with Innovative Solutions

Rubber Powder Modified Asphalt

In Africa, the adoption of rubber powder in modified asphalt is still in the early stages, but countries like

South Africa are leading the way in research and pilot projects. Given the continent’s diverse climatic and

geographic conditions, rubberized asphalt offers a promising solution to the challenges of road durability

and maintenance. Early results from pilot projects have shown potential for reduced road maintenance costs

and improved performance, indicating a bright future for rubberized asphalt in Africa’s road infrastructure.

Success Stories Highlighting the Global Impact

The global narrative of rubber powder in modified asphalt is filled with success stories that

underscore its benefits. For instance, in Saudi Arabia, the use of rubberized asphalt has demonstrated significant

improvements in road performance, particularly in terms of heat resistance and longevity, crucial factors in the country’s

arid climate. Similarly, pilot projects in European countries have reported not only enhanced road

durability but also notable decreases in road noise, contributing to improved urban living conditions.

Conclusion: A Path Towards Sustainable Global Rubber Powder Modified Asphalt

These success stories from across continents illustrate the universal applicability

and benefits of rubber powder in modified asphalt. By adopting this innovative solution, countries

are not only addressing environmental and economic challenges but also paving the way towards more

sustainable and resilient road infrastructure. The continued sharing of knowledge and experiences among

nations will undoubtedly propel the global adoption of rubberized asphalt, marking a significant step forward in the

quest for sustainable development.

Why Choose Our Rubber Granules?

🌿 Eco-Friendly: Embrace sustainability without sacrificing quality. Our rubber granules are produced with environmental preservation in mind.

⚖ Durability & Safety: Engineered for resilience and safety, ensuring your projects stand the test of time with top-notch performance.

💸 Cost-Effective: Get the best value for your investment. High quality meets affordability in our rubber granules, tailored for both large-scale and smaller projects.

🌎 Global Export Expertise: Rubber Powder Modified Asphalt

With a strong track record in exporting globally, we guarantee a smooth and efficient supply chain process to deliver right to your doorstep.

Transform your project with our Rubber Powder & SBR rubber granules, the best choice for those who prioritize quality, sustainability, and cost-effectiveness. Your search for the best supplier ends here!

📞 Contact us at 00201096165656 to discover how our rubber Powder & granules can revolutionize your projects.

Visit our FaceBook : IM TRUST FB

#RubberPowder #RubberGranules #SBR #ModifiedAsphalt #AsphaltAdditives #ConstructionMaterials #RubberSupplier #SBRSupplier #PowderSupplier

#RoadConstruction #Infrastructure #EcoFriendlyMaterials #SustainableSolutions

#RubberGranules #EcoFriendly #SustainableMaterials #IndustrialSolutions #ExportExcellence #BestSupplier #CostEffective

Black Asphalt Crumb Rubber / Rubber Powder Modified Asphalt

Black Asphalt Crumb Rubber / Rubber Powder Modified Asphalt